New Engines and Changing the Hull Color

We enjoyed the boat on the Hudson for several years after rebuilding the hull. Nevertheless, we were still dealing with old Chrysler 318 engines from 1962. They were cantakerous and I became thankful for two engines because so many times I had to limp back on a single engine. I once had the boys jump off the boat and get our dinghy to use as a tug to push the bow to turn while docking because of a dead engine. Just as bad, one or both had a tendency to die when you got into a tight space for docking. This led to some ugly scenes because the boat isn't very maneuverable on a single engine. It easly goes straight but anything else was really tough. Why don't you just restart the engine, you ask? Well, they were very hard to get restarted once they died. I kept a very important can of starting fluid (spray ether and highly volatile and explosive, a.k.a. "Panther Piss") in the locker for just those situations. Scenes like in Liberty Landing Marina with an approaching thunderstorm trying to turn around and losing an engine, being blown towards boats without the ability to stop unless I get the stalled engine started. With liberal starting fluid and prayer, the engine came to life to allow me to avoid a crash at the last minute.

Eventually, we expanded off the Hudson River to Long Island Sound and the discovery of Shelter Island where it became our summer spot. All of the extra running up and down the sound only accelerated the decline of these aging engines. After 8 years, they had pretty much cashed out. They were V8 engines with 4 dead cylinders each.

In addition to the dying engines, the boat was starting to suffer from being out in the weather as a wooden boat. In Virginia, we had covered boathouses that kept the boats out of the weather. That's what kept it alive all of these years. A wooden boat sitting in salt water in a boathouse is pretty inert and safe. Unfortunately, north of the Delaware, boathouses don't exist due to the greater tidal movement. While Virginia has 3' tides, New York has 5-6' tides. After being out in the weather for 8 years, I was fighting rot on the decks and sides and it was starting to look tired.

So the plan was to repower the boat and, while the engines were out of the boat, I would repaint the engine room as well as the entire boat. Another item was to deal with the squeezed out seam compound from the hull rebuild 8 years earlier. This was a natural by-product of rebuilding the hull and putting in seam compound with dry, shrunken boards. As the boards swelled from being in the water over the following years, they squeezed out a pretty good portion of the seam compound. So each seam now had a ridge that had to be taken down. It was the worst under the boat with the widest planks having the greatest amount of wood per seam to expand. While a white hull is the standard color of a boat hull, I had gotten tired of the white because it showed dirt so easily and always had black streaks. So I also changed the color to black. The last item was to change the rudders. More on that later.

I started working on the boat in March 2016 where I would drive out early Saturday morning, work until dark, start at first light on Sunday and drive back that night. That was my schedule until August. As the days grew longer, I calculated that I could cram in 24 hours of work into those two days. While I work out at the gym lifting weights, it's all of the little muscles that you don't get to use that I was suddenly discovering at the outset. After a few months, I was out of pain and in shape for the long weekends. Nevertheless, it was good to have 5 days of office work between these sprint weekends.

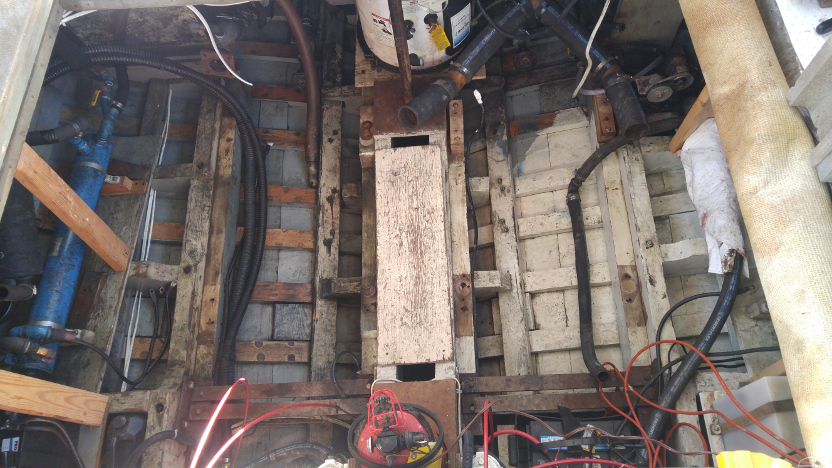

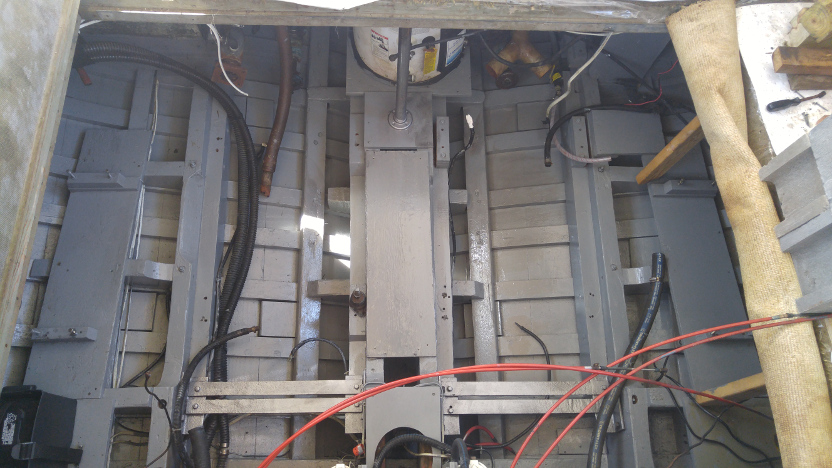

The first task was to clean and paint the engine room now that the

engines were out. The boatyard had cut a hole in the roof in order to

take out/in engines because there previously was no good way to remove/replace an

engine. In previous times, I've gotten a disassembled block through the doorway on a

dolly and then reassembled the engine, we've used forklifts to pass

through a side window and ultimatley breaking the window. It always needed a

hatch. Once the engine room was cleaned and painted, the engines were

put in through the new hatch. The new engines are still gas for now to

minimize the amount of change. They are Crusader 350 cubic inch

engines which are a marinized version of a Chevrolet 350 truck engine.

With that done, the work started on the hull. The first task was to

use a grinder to take down the seams to be flat and remove the ridges

from the seam compound. The whole hull had to be resanded in order to

remove the pushed seam compound and get the hull smooth enough to

paint. Mary-Powel came out to help sand one weekend. It's true love

when your wife crawls under the boat wearing a dust mask to sand down

the hull!

While running a sander for hours, you have time to think about

things. So mid-job as I was removoing the metal parts on the hull, I

had the idea that instead of putting back on as they are, to instead

get them rechromed. They were originally chromed bronze fittings and

the chrome had long worn off. So I organized the various parts needing

rechroming and took them off to

Nassau Chromium Plating

who did a great job. My thinking was that a black hull will show

chrome much easier and it was a quick visual victory.

As mentioned, the rudders needed to be changed. The original

1953 rudders on the boat were borderline dangerous in a following

sea because they don't go deep enough to control it. Thus, the boat was

very hard to control with many worrying moments whether the rudders

would catch before we're knocked sideways. Once, we broached coming through Plum Gut in

a following sea one very rough day - not fun. My friend, Barry, who did

much of the hull rebuild in 2007, had parts off of other dead

Matthews boats. One of the parts was a pair of rudders off of a

mid-1960's Matthews the same size as mine. The difference being that

the boatbuilder had come up with deeper rudders in the 15 years

between the boats. Controlling these boats in a following sea has been mentioned before

among fellow members of the Matthews Boat Owners Association.

I was all to happy to make a swap. Here, you can

see the difference between the two as one original rudder remained

in and a new one has been put in. These rudders have proved themselves a godsend in later years with following seas.

While the boat was being worked on, another item to address were

the boat's original Stewart Warner engine gauges. These gauges were

mechanical: the oil pressure, temperature, and tachometer were all run

by a pressure tube, a burdon tube, and a drive cable respectively. All

of them were at the ends of their service lives. I wanted to keep the

original look at the helm so I sent them off to

Clawson Classic Instrumentation

to have their internals replaced with electronic gauges while

retaining the same look.

As the black paint started to go on the hull, I got pretty

excited as the end of the project was in sight and the season could

begin.